Why invest in Agilyx?

Agilyx is a publicly traded, technology-agnostic leader in the plastic recycling sector, trusted by blue-chip partners. We present a strong, diversified-exposure investment opportunity in the advanced recycling industry with funded projects that promote future growth and present a clear path to profitability.

Agilyx at a glance

A publicly traded company

Listed on the Oslo Stock Exchange (OSE) since September 2022, with a market capitalization* of NOK 2.74b (USD 272m)

*As of 29 August 2025

Two industrial-scale Cyclyx Circularity Centers in construction

The two USA-based centers have a combined capacity to produce approximately 150ktpa of custom feedstock for advanced recycling technologies.

On advanced recycling technology

Eight generations of technology development, a polystyrene waste recycling facility running on Styrenyx advanced recycling technology licensed to Toyo Styrene (a member of Denka Group), and 22 patents active in North America, the Middle East, Mexico and Asia.

Given the complexity of plastics, and the difficulty in sourcing post-use plastics,

feedstock availability is a enormous industry BOTTLENECK

With seven primary types of plastic and countless combinations of additives and contaminants, the plastic waste stream is incredibly complex and poses significant challenges for recyclers. Despite high demand for quality feedstock, many materials including films, foams, and multi-layer packaging are not widely accepted in easily accessible recycling services (curbside systems and drop-off facilities), leading to inconsistent recovery and limited supply. Adding to this challenge, each recycling technology requires a specific feedstock profile to operate efficiently.

Plastyx will address the feedstock supply shortage

New regulations and increased consumer environmental awareness are pressuring brands to increase their recycled content targets.

By 2030, advanced recycling supply capacity will lag announced required demand by 50%. This creates a significant challenge accessing appropriate feedstock to supply advanced recycling production facilities.

Plastyx is rising to the challenge by acting as a feedstock aggregator and pretreatment processor of European-sourced plastic waste

Source: ICIS, Plastyx Market Intelligence, McKinsey

New regulations and increased consumer environmental awareness are pressuring brands to increase their recycled content targets.

By 2030, advanced recycling supply capacity will lag announced required demand by 50%. This creates a significant challenge accessing appropriate feedstock to supply advanced recycling production facilities.

Plastyx is rising to the challenge by acting as a feedstock aggregator and pretreatment processor of European-sourced plastic waste

Source: ICIS, Plastyx Market Intelligence, McKinsey

Cyclyx offers tailored feedstock solutions for recycling technologies

Cyclyx stands alone in creating custom-formulated feedstock derived from post-use plastics for both advanced and mechanical recycling processes. Precision is made possible through proprietary technology encapsulating an extensive database cataloging the complexity of post-use plastics, chemical characterization and management, and state-of-the-art sortation and processing.

Cyclyx stands alone in creating custom-formulated feedstock derived from post-use plastics for both advanced and mechanical recycling processes. Precision is made possible through proprietary technology encapsulating an extensive database cataloging the complexity of post-use plastics, chemical characterization and management, and state-of-the-art sortation and processing.

Two Cyclyx Circularity Centers in the pipeline

The first center is under construction in Houston and is expected to start operations in 2025. The second is located in Dallas-Fort Worth, with an expected start of operations in 2026.

Strong growth in feedstock demand is supported by market conditions, presenting a unique investment opportunity in plastic recycling infrastructure.

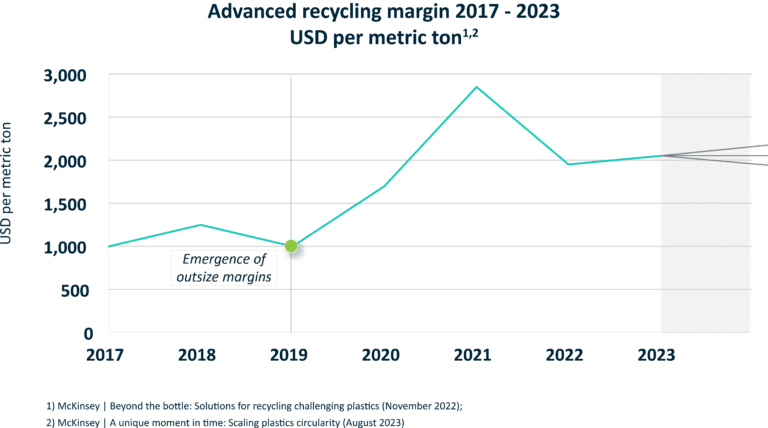

There is substantial profit potential in the recycled plastics market

$2,000 per metric ton

Significant margins of up to $2,000 per metric ton available throughout the value chain

McKinsey: A unique moment in time: Scaling plastics circularity

$1,500 premium

Plastics derived from advanced recycling processes are commanding a premium, often selling for $1,500 or more per metric ton compared to traditional fossil fuel-based plastics.

McKinsey: Beyond the Bottle: Solutions for recycling challenging plastics

Premiums driven by a significant supply-demand imbalance

These high premiums are driven by a significant supply-demand imbalance. The availability of feedstock for advanced recycling lags behind announced capacity by as much as 60%.* Addressing this demand highlights the vital importance of Cyclyx Circularity Centers in fostering circularity and improving the handling of post-use plastic waste.

*Wood Mackenzie