Recovering the value of plastic waste by transforming it into premium feedstock for sustainable solutions

Cyclyx is on a mission to increase the recyclability of post-use plastics, regardless of origin, composition, or condition by delivering high-quality feedstock from materials once considered unrecyclable.

From collection to new, virgin-equivalent material

Expanded collection

Cyclyx’s systems accept difficult-to-recycle plastics, like plastic films, flexibles, and multi-laminates, recovering more plastic, more effectively—turning waste into value at scale.

Innovative systems

Using proprietary technology and advanced sorting capabilities, Cyclyx can analyze, blend, and custom-formulate recycled feedstock to meet customer specifications. Solutions are innovative and data-driven.

Feedstock to product

ISCC-PLUS certified feedstock is converted into valuable, lower-carbon material that can be used in the production of new plastics and products that make modern life possible.

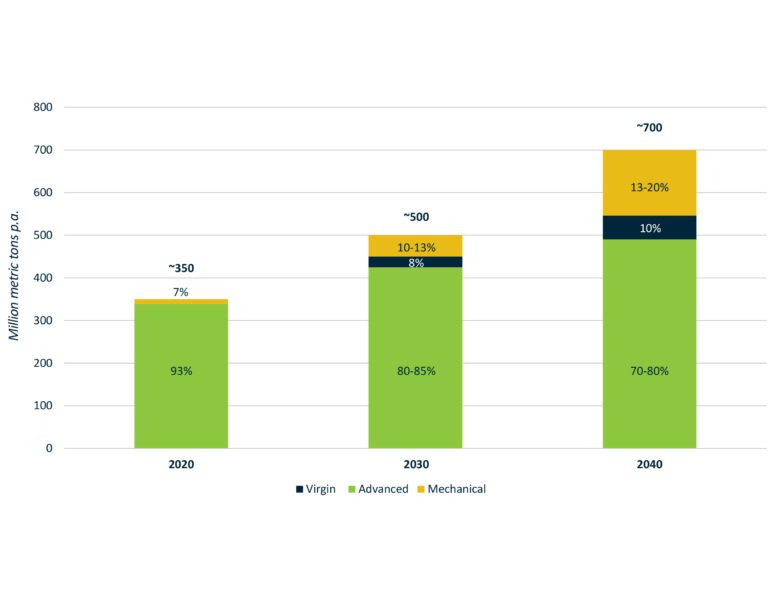

353 million tons of plastic waste generated yearly, less than 10% is recycled*

One of the biggest barriers to plastic recycling is lack of feedstock from plastic waste.

The lack of high-quality feedstock is a major industry bottleneck that curtails the potential of increased advanced recycling capacity

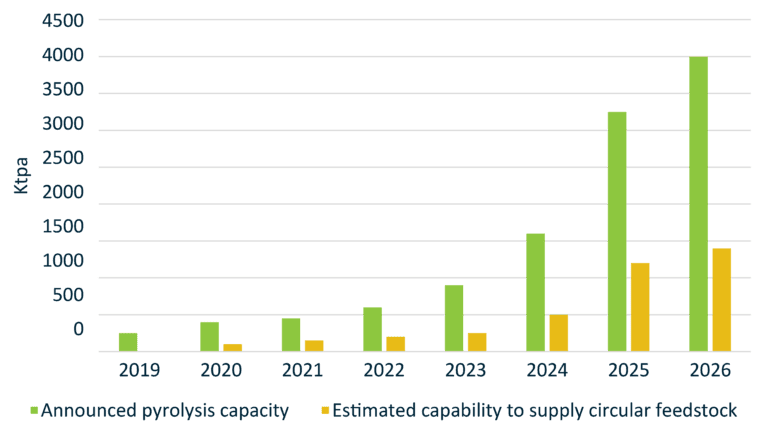

Supply of plastic feedstock lags existing pyrolysis capacity by an estimated 60%*. Innovative post-use plastic sourcing, sorting, and characterization are needed to meet feedstock demand.

The industry struggles with the management and infrastructure necessary to deliver the right type of feedstock to those who can recycle it best.

Cyclyx was formed to address one of the toughest challenges in recycling today: how to efficiently manage plastics that traditional systems can’t process.

Chart: Wood Mackenzie

Projected demand for recycled material is increasing, creating a significant opportunity for Cyclyx Circularity Centers to provide plastic waste feedstock

Near term, feedstock demand and investment in innovative recycling solutions are forecasted to grow at record pace.

By 2030, an estimated 67 MM tons p.a. of incremental processing capacity will be required to supply sufficient feedstock to the recycling industry. Meeting this demand underscores the need for hundreds of plastic processing facilities across the U.S. and globally.

What is a

Cyclyx Circularity Center?

Cyclyx Circularity Centers are first-of-their-kind facilities capable of accepting a wide range of post-consumer, commercial, and industrial plastic waste and custom-formulating it into ISCC-PLUS-certified feedstock for mechanical and advanced recycling applications.